In the high-stakes world of racing, where every millisecond counts, the performance of a vehicle’s engine is paramount. Engine failures not only result in potential damage to the vehicle but can also jeopardize a racer’s position or even their safety on the track. Recognizing the common causes of engine failures is crucial for teams and drivers dedicated to securing victory.

A racing engine operates under extreme conditions, facing challenges that everyday vehicles seldom encounter. The intense heat, high RPMs, and the need for quick acceleration can lead to various engine issues if not properly managed. Understanding these factors and the common types of failures can help teams implement preventive measures, ensuring their engines remain highly functional and reliable throughout the race.

Every racing enthusiast knows that preventative maintenance is the key. Regular checks and proactive strategies can mitigate the risks of engine failures. This involves not only routine inspections but also a deep understanding of the engine’s components and their vulnerabilities. By focusing on best practices to minimize wear and tear, teams can protect their engines from suffering the irreparable damage that could end their racing dreams.

Identifying Early Signs of Engine Damage in Racing Conditions

In the high-stakes world of motor racing, detecting early signs of engine damage can make the difference between victory and failure. Engine reliability is crucial, and racers must be vigilant in monitoring their engines for any indicators of potential issues.

Recognizing early symptoms can help mitigate risks associated with engine failures, allowing for timely interventions and repairs. Below are common signs that may indicate engine damage:

- Unusual Noises: Knocking, rattling, or grinding sounds can signal internal engine damage. These noises should never be ignored as they often indicate severe mechanical issues.

- Loss of Power: A noticeable drop in performance or reduced acceleration may suggest engine wear or malfunction. Drivers should regularly assess their vehicle’s throttle response.

- Excessive Smoke: Emission of smoke from the exhaust is a red flag. White smoke may indicate coolant leaks, while blue smoke often points to oil burning. Both require immediate attention.

- High Operating Temperature: Racing conditions can lead to overheating. If gauge readings exceed normal limits, it may suggest coolant loss, a broken thermostat, or other cooling system failures.

- Fluid Leaks: Puddles or spots under the vehicle can imply fluid leaks, whether oil, coolant, or transmission fluid. Identifying the source of the leak can prevent catastrophic engine failure.

- Engine Warning Lights: Utilizing advanced diagnostic tools is essential. If warning lights activate, it indicates that something is amiss and should be investigated immediately.

Additionally, regular monitoring of the vehicle’s performance metrics during races can provide insight into engine health. Implementing a systematic check after each racing event can aid in detecting problems before they escalate.

In conclusion, being proactive in identifying early signs of engine damage not only enhances racing performance but also significantly reduces the risks associated with engine failures. Awareness and maintenance are key to ensuring that the engine continues to perform optimally throughout the racing season.

Essential Maintenance Checks Before Race Day

Prior to race day, ensuring that your engine is in optimal condition is crucial for mitigating the risks associated with racing. Conducting thorough maintenance checks can help identify potential issues that may lead to engine failures during a race.

First, inspect the engine oil level and quality. Fresh, clean oil is vital for effective lubrication, reducing friction, and maintaining engine temperature. Change the oil and oil filter if the oil appears dirty or has not been changed recently.

Next, examine the cooling system. Check coolant levels and look for leaks in hoses and connections. A properly functioning cooling system prevents overheating, which can severely damage the engine during high-performance racing conditions.

Fuel quality should also be evaluated. Ensure that the fuel system is clean and that no contaminants are present. Using high-octane fuel suitable for your engine type can enhance performance and prevent pre-ignition and knocking.

Tire condition and pressure are equally important. Inspect tire tread and sidewalls for any signs of wear or damage. Proper tire pressure enhances grip and handling, significantly impacting engine performance during a race.

Don’t overlook the battery. Check connections and test the battery voltage. A weak battery can lead to starting issues, which can become critical, especially in a racing environment.

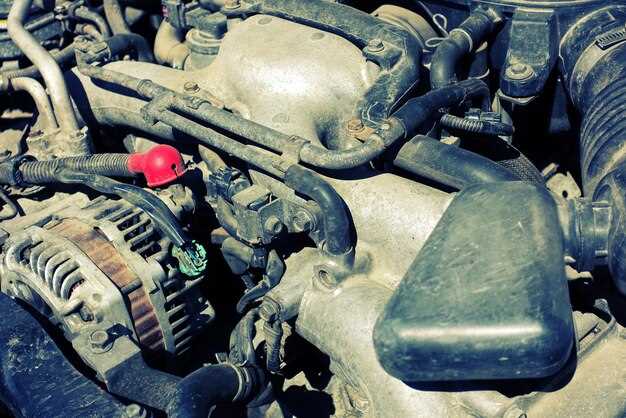

Finally, perform a complete visual inspection of the engine for any signs of wear, leaks, or loose components. Early identification of these issues can prevent significant engine failures on race day.

Strategies to Mitigate Racing Risks and Protect Engine Integrity

In the high-octane world of racing, ensuring engine integrity is paramount for success and safety. A proactive approach can significantly reduce the risk of damage that race engines often encounter. Here are several effective strategies to mitigate racing risks and safeguard engine performance.

Regular maintenance is the backbone of engine reliability. Perform thorough inspections on critical components such as oil pumps, cooling systems, and turbochargers. Ensure that oil levels are optimal and that the oil used meets specific viscosities suited for extreme conditions. This minimizes wear and helps maintain engine temperature within safe limits.

Utilizing high-quality fuel tailored for racing applications is essential. Impurities or incorrect fuel grades can lead to pre-ignition, causing catastrophic damage. Conduct regular fuel tests to ensure consistency and quality, and adjust fuel mixtures based on track conditions and engine tuning.

Advanced cooling systems can significantly enhance engine protection. Consider installing high-performance radiators and intercoolers to maintain optimal temperatures during races. Additionally, thermal management solutions, such as engine blankets or heat shields, can help reduce thermal stress on engine components.

Data acquisition systems are invaluable for monitoring engine performance in real-time. Use sensors to track vital information such as temperature, pressure, and RPM. Analyze this data to identify potential issues before they escalate into significant problems, allowing for timely intervention.

Establishing a stringent pre-race checklist ensures that every aspect of the engine is scrutinized. This includes verifying all connections, checking for leaks, and ensuring that all components are functioning properly. A focused approach helps in identifying early signs of trouble.

Lastly, employing a robust driving strategy can also lessen engine strain. Encourage drivers to be mindful of throttle control during races. Avoiding aggressive acceleration and deceleration can minimize stress on engine components, thereby prolonging its lifespan and enhancing overall performance.